Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

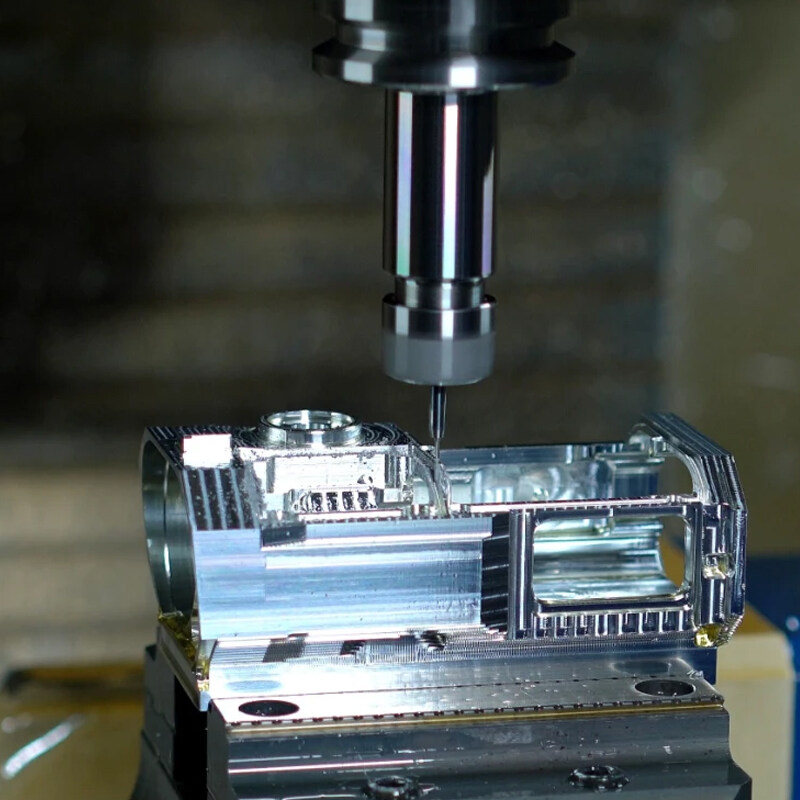

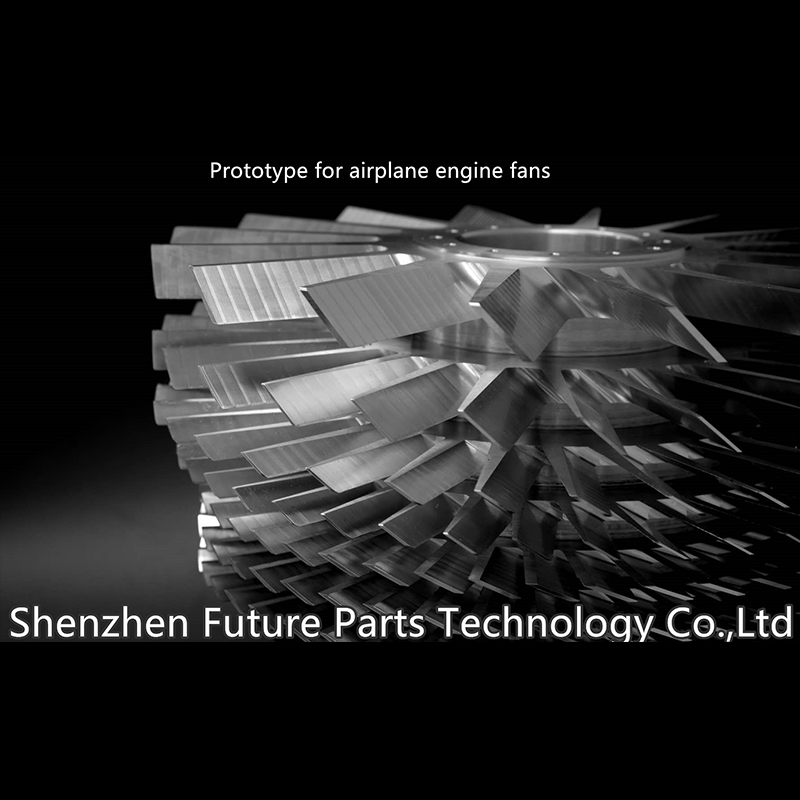

CNC machining service

For engineers, product developers, and designers who require prototyping and low-volume production, Future Parts' custom CNC services are the solution. Whether it's a simple or intricate design with tight tolerances, our ISO 9001 certified CNC machine shops ensure excellence. Our fast CNC machining capabilities guarantee the delivery of quality custom machined parts within 1 day.

What is CNC Machining?

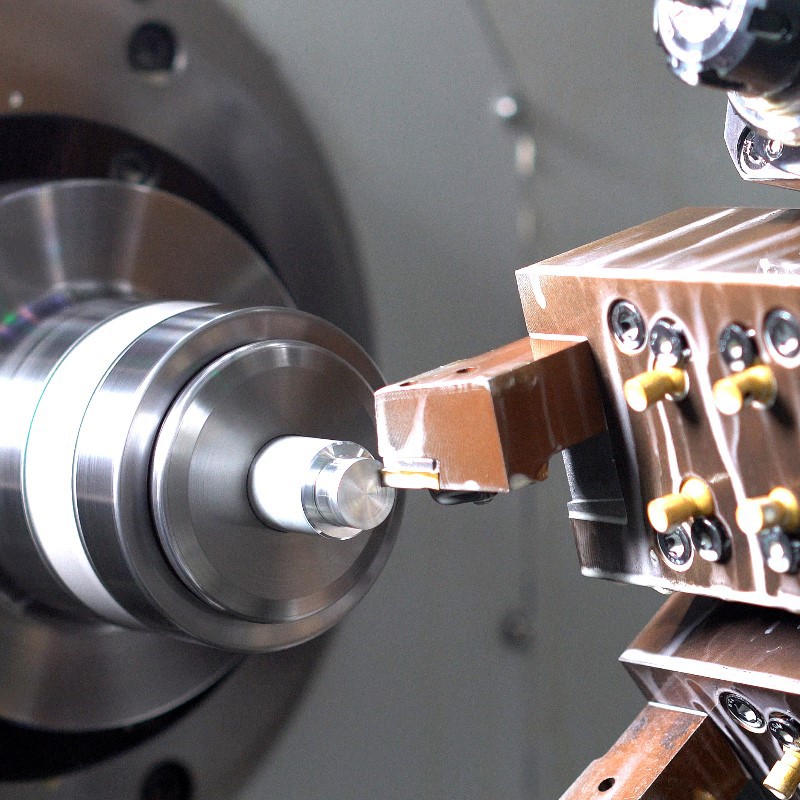

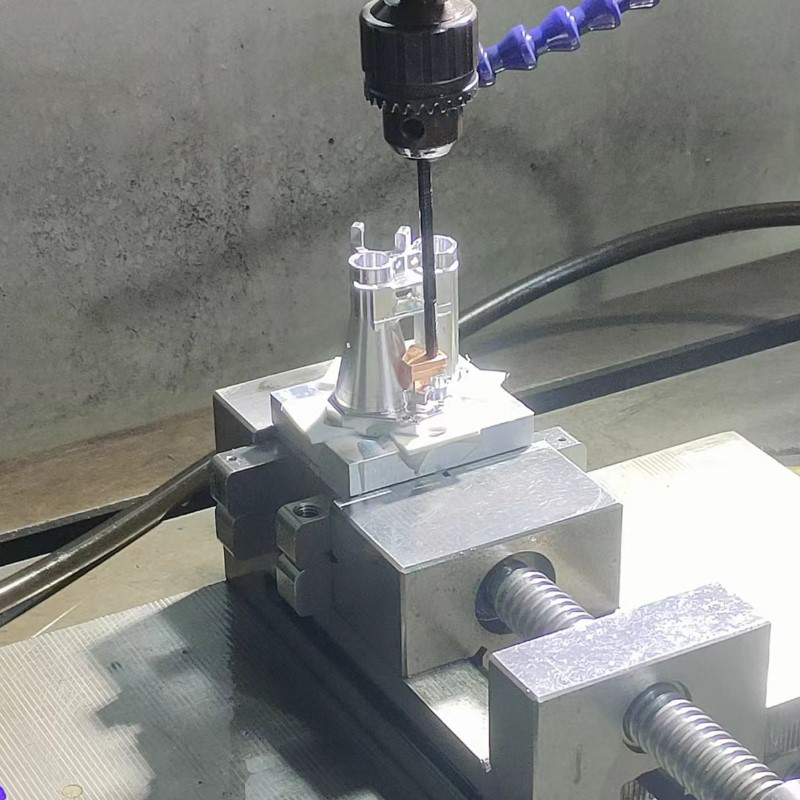

CNC Machining, or Computer Numerical Control Machining, is a manufacturing technique where computer-controlled devices are used to remove layers from a material, creating detailed parts or components. Through a combination of tooling and precise machine movement, it produces parts to exact specifications.

- CNC Machining Materials

A number of materials can be used in CNC machines, giving you various of options to complete rapid prototyping to production runs of custom complex parts. For your manufacturing needs, we provide instant quotations of 40+ metals and plastics, and even you can compare prices for different machining materials.

Common materials including: aluminum, copper, brass, stainless steel, titanium, plastic(POM,PEEK,HDPE,PET,Nylon,PITE, PVC, PP, ABS, PC, PMMA),etc.

- CNC Machining Surface Finishes

CNC machining leaves visible tool marks during the process of removing portions of the block’s surface to create desired shapes. If don’t want as-machined parts, select a surface finishing for your custom parts. At Future Parts, we offer several common surface finishes that help improve functionality and aesthetics.

- CNC Machining Tolerances

For metals, Future Parts CNC machining service follows the ISO 2768-m standard, and for plastics, we follow ISO 2768-c. For custom tolerances, please mark them clearly on your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 4000x 1500*<600 mm 157.5x59.1x23.6 in. |

200x500 mm 7.9x19.7 in. |

| Minimum Part Size | 4x4 mm 0.1*0.1 in. |

2x2 mm 0.079*0.079 in. |

| Minimum Feature Size | φ0.50 mm φ0.00197 in. |

φ0.50 mm φ0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-m Plastics: ISO 2768-c |

Metals: ISO 2768-m Plastics: ISO 2768-c |

| Linear Dimension | 士0.025 mm 士0.001 in. |

士0.025 mm 士0.001 in. |

| Hole Diameters (Not Reamed) |

士0.025 mm 士0.001 in. |

土0.025 mm 士0.001 in. |

| Shaft Diameters | 士0.025 mm 士0.001 in. |

士0.025 mm 士0.001 in. |

| Edge Condition | Sharp cormners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radi, must be indicated on the drawing. |

|

| Threads and Tapped Holes |

Diameter: φ 1.5-5 mm, depth: 3xdiameter Diameter: φ 5 mm or more, depth: 4-6xdiameter |

Diameter: φ 1.5-5 mm, depth: 3xdiameter Diameter: φ 5 mm or more, depth: 4-6xdiameter |

| Future Parts can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of0.5 mm, depth of 0.1 mm Future Parts can use CNC engraving or laser carving to create standard text based on customers'requirements. |

Future Parts can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 5 working days | 5 working days |

The Advantage of product

CNC Machining offers unparalleled precision and repeatability, making it a top choice for industries requiring intricate parts. Its ability to handle a variety of materials, from metals to plastics, combined with fast production times and consistent quality, makes it an essential method in modern manufacturing.

CNC machining offers many advantages for product developers, including:

- Fast material removal

- Tight tolerances and high precision

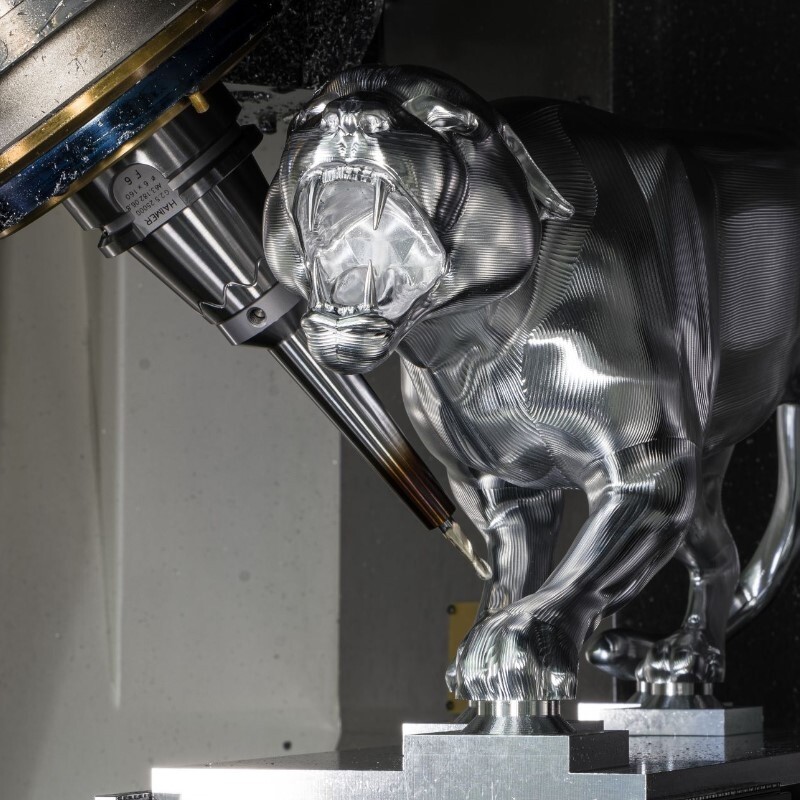

- Excellent for making complex geometries

- Versatile

- Suitable for many different kinds of substrates

- Unlimited volumes

- Low investment in tooling

- Fast turnaround

- Parts are full-strength

- Excellent surface finishes

- Easily customized

The Feature of product

- Speed: CNC machining is known for its fast production capabilities. It can quickly produce parts, reducing lead times and allowing for faster product development and delivery.

- Accuracy: CNC machines are highly precise and can consistently produce parts with tight tolerances. This ensures that the final product meets the required specifications and quality standards.

- Versatility: CNC machining can handle a wide range of materials, including metals, plastics, and composites. It can also accommodate various part sizes and complexities, making it suitable for a diverse range of applications.

- Cost-effective: CNC machining eliminates the need for expensive tooling or set-ups. This means that it is a cost-effective solution for both prototyping and low-volume production. It also allows for easy design modifications and iterations without incurring additional costs.

The Application of product

- Our precision CNC machining services make complex finished parts and components as well as tools for plastic injection molding or pressure die casting. In addition, CNC manufacturing is used for secondary drilling, tapping, and milling operations on machined parts or parts made from other processes.

- CNC machine tools come in many specialized types to perform all kinds of operations on raw stock. However, CNC mills are the most common and versatile multi-axis machines that we use at Future Parts every day.